Lis . 19, 2024 07:15 Back to list

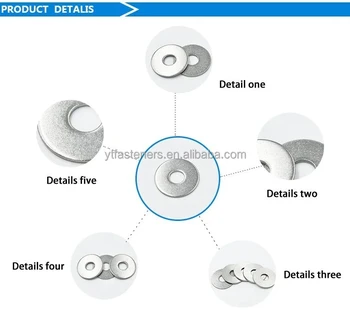

4 inch flat washer

The Importance of 4-Inch Flat Washers A Comprehensive Overview

When it comes to construction, automotive applications, or DIY projects, it’s often the smallest components that play a vital role in ensuring the whole assembly functions efficiently and effectively. One such component is the flat washer, particularly the 4-inch flat washer. These seemingly inconspicuous circular plates are essential in distributing weight and load, protecting surfaces, and providing a stable support system for various applications. This article delves into the various aspects of 4-inch flat washers, exploring their materials, uses, advantages, and installation considerations.

What is a Flat Washer?

A flat washer is an engineering component traditionally made from metal, although they can also be manufactured from plastic or rubber. Washers come in various sizes and thicknesses, tailored to accommodate specific applications. The primary function of a flat washer is to spread the load of a threaded fastener, such as bolts and nuts, thereby reducing the likelihood of damage to the surface being fastened. In the case of a 4-inch flat washer, its significant diameter offers substantial surface area, making it particularly useful in high-load applications.

Materials and Manufacturing

4-inch flat washers can be manufactured from a variety of materials, each chosen based on the specific requirements of the application. Common materials include

1. Steel Often galvanized or coated to resist corrosion, steel washers offer strength and durability for heavy-duty applications. 2. Stainless Steel For environments where corrosion resistance is paramount, stainless steel washers are ideal. They offer both strength and resistance to rust, making them suitable for outdoor and marine applications. 3. Plastic Nylon or other plastic washers serve as insulators and are often used in electrical applications. 4. Rubber These washers provide cushioning and sealing properties, making them effective for applications requiring vibration isolation or water resistance.

The choice of material not only impacts the washer's performance but also determines its resistance to environmental factors like temperature, moisture, and chemicals.

Applications of 4-Inch Flat Washers

The applications for 4-inch flat washers are vast and varied

. Here are some prominent uses4 inch flat washer

1. Construction Industry Used extensively in building structures, flat washers help secure beams, columns, and other components, ensuring stability and load distribution. 2. Automotive In vehicles, these washers can be found in suspension systems, engine components, and chassis alignments, contributing to the overall safety and performance. 3. Manufacturing Machinery often requires flat washers to ensure proper assembly and functioning, preventing wear and tear on critical components over time. 4. Home Improvement DIY enthusiasts and homeowners utilize flat washers in various projects, from furniture assembly to plumbing, showcasing their versatility and practicality.

Benefits of Using 4-Inch Flat Washers

The advantages of employing 4-inch flat washers in applications are manifold

1. Load Distribution By increasing the bearing surface area, these washers help distribute the load across a broader area, reducing stress on individual components and enhancing their longevity. 2. Protection Flat washers protect the surface being fastened from damage caused by the fastener, which is particularly beneficial in materials that are prone to denting or deformation. 3. Vibration Absorption When used in conjunction with specific materials, flat washers can absorb vibrations, which is crucial in applications where movement or oscillation can lead to loosening and failure. 4. Corrosion Resistance Depending on the material used, flat washers can provide excellent resistance to rust and degradation, ensuring reliability in adverse conditions.

Installation Considerations

When installing 4-inch flat washers, there are several factors to consider

1. Correct Sizing Ensure the washer is appropriately sized for the fastener and application. An oversized or undersized washer can lead to ineffective load distribution. 2. Surface Preparation Clean the surfaces where the washer will be placed to ensure a secure and stable connection. 3. Torque Specifications Adhere to recommended torque specifications to avoid over-tightening, which can damage both the fastener and washer.

Conclusion

In conclusion, the 4-inch flat washer is a fundamental yet crucial part of many mechanical assemblies. Its ability to enhance load distribution, provide protection, and increase component longevity makes it indispensable across various industries. By understanding their function, materials, and proper installation techniques, users can maximize the efficiency and effectiveness of their projects. Whether you are a contractor, a mechanic, or a DIY enthusiast, recognizing the importance of flat washers can lead to better outcomes in your work.