सितम्बर . 28, 2024 15:18 Back to list

Understanding M12 Nut Dimensions and Specifications for Precision Engineering Applications

Understanding M12 Nut Size A Comprehensive Guide

In the world of fasteners, the term M12 nut refers to a specific type of metric nut that fits a bolt with an M12 thread size. The M indicates that the nut is part of the metric system, which is widely used across many countries for industrial and construction purposes. The number 12 denotes the nominal diameter of the bolt, which is 12 millimeters. This seemingly small detail plays a significant role in ensuring the proper assembly and function of mechanical systems.

The Importance of Proper Sizing

Choosing the correct nut size is critical for the success of any assembly project. An M12 nut is designed to be used in conjunction with an M12 bolt. Using an incorrect nut size can lead to a variety of issues, including reduced joint strength, misalignment, and increased wear on both the nut and the bolt. In some cases, using a nut that is too small can lead to stripping, rendering the fastener useless.

When selecting an M12 nut, it’s essential to consider not just the size but also the material. M12 nuts are available in a variety of materials, including carbon steel, stainless steel, and nylon. Carbon steel nuts offer great strength and are often coated to prevent corrosion, while stainless steel nuts provide enhanced resistance to corrosion and are ideal for use in challenging environments. Nylon nuts, while not as strong as their metal counterparts, have unique properties that allow for some flexibility and are useful in applications where weight is a concern.

Thread Types and Standards

M12 nuts come in various thread types and standards, most commonly the standard metric threads (ISO 965) or fine threads (ISO 724). The standard M12 nuts generally have a coarse pitch of 1.75 mm, while fine-thread variants come with a pitch of 1.5 mm. The pitch is the distance from one thread to the next and significantly influences the nut's grip on the bolt. Coarse threads provide better resistance to stripping and are easier to install, while fine threads allow for finer adjustments and higher tensile strength.

m12 nut size

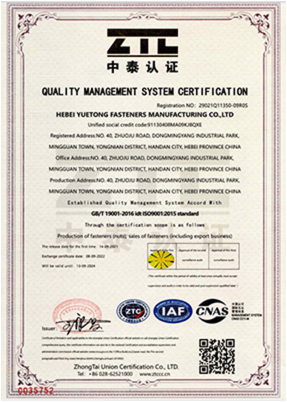

When purchasing M12 nuts, it’s crucial to ensure compatibility with the specific use case. Manufacturers provide detailed specifications, including tensile strength ratings, that can help determine the right type of nut for a given application. For high-stress applications, it might be advisable to use nuts that meet specific standards, such as those certified by ASTM or ISO.

Applications of M12 Nuts

M12 nuts are commonly used in various sectors, including automotive, construction, machinery, and electronics. In automotive applications, they secure components in engines, transmissions, and various assemblies. In construction, M12 nuts can fasten structural elements, ensuring stability and safety. In electronics, they might be used to secure circuit boards or other delicate components.

The versatility and reliability of M12 nuts make them an essential part of many engineering projects. Whether in simple DIY tasks at home or complex industrial applications, the right choice of nuts can make all the difference in achieving a durable and effective assembly.

Conclusion

In summary, understanding the M12 nut size is fundamental for anyone working with metric fasteners. From knowing the appropriate thread type to selecting the right material, every detail matters in ensuring the effectiveness and safety of mechanical assemblies. By choosing the correct M12 nuts, you can enhance the longevity and performance of your projects, ensuring that they stand the test of time. In industries where precision is key, investing in the right fasteners can lead to improved outcomes and reduced maintenance costs, ultimately benefiting both the manufacturer and the end-user.

-

The Ubiquitous Reach of DIN934 in Application Realms

NewsMay.16,2025

-

Exploring Different Bolt Types

NewsMay.16,2025

-

Cracking the Code of Sleeve Anchor Mastery

NewsMay.16,2025

-

Clamp Design Principles,Types and Innovations

NewsMay.16,2025

-

Artistry Inspired by the Humble Anchor Bolt

NewsMay.16,2025

-

A Deep Dive into Screw Types

NewsMay.16,2025