okt . 05, 2024 06:12 Back to list

choosing bolt size

Choosing Bolt Size A Comprehensive Guide

When embarking on any construction or manufacturing project, choosing the right bolt size is a crucial step that can significantly affect the stability and durability of the structure you're working on. While it might seem like a trivial aspect at first glance, the implications of using the wrong bolt size can lead to structural failures, safety hazards, and increased costs. This article will guide you through the essential factors to consider when selecting the appropriate bolt size for your project.

Understanding Bolt Measurements

Bolts are generally characterized by their diameter, length, thread pitch, and strength grade. The diameter is measured across the thread, typically in inches or millimeters, while the length is measured from the underside of the head to the end of the bolt. Thread pitch is the distance from one thread crest to the next and can significantly influence how well the bolt will hold when installed.

Factors Influencing Bolt Size Selection

1. Load Requirements The first step in choosing the right bolt size is to assess the load requirements of your application. This includes both static loads, which are constant over time, and dynamic loads, which may change due to movement, vibration, or impact. The load-bearing capacity of a bolt increases with its diameter, so it’s essential to calculate the expected loads accurately to ensure you choose a bolt that can handle them safely.

choosing bolt size

2. Material Compatibility The material of the bolt must also be compatible with the materials it will be fastening together. Common bolt materials include steel, stainless steel, and aluminum. Each material has different strength characteristics that can affect performance. For example, stainless steel bolts are excellent for corrosion resistance, making them suitable for outdoor or marine applications, while high-strength steel bolts may be more appropriate for heavy structural applications.

3. Environmental Conditions Consider the environmental conditions that the bolt will be exposed to. Factors such as humidity, temperature extremes, and exposure to chemicals can impact the longevity and reliability of a bolt. In harsh environments, using bolts with appropriate coatings or materials that resist corrosion and wear is vital.

4. Joint Configuration The type of joint being fastened also plays a critical role in bolt size selection. Various applications—such as shear or tensile loads—will require different bolt configurations and sizes. For example, bolting two pieces of metal together may require a heavier-duty bolt than what is needed for fastening light wood components.

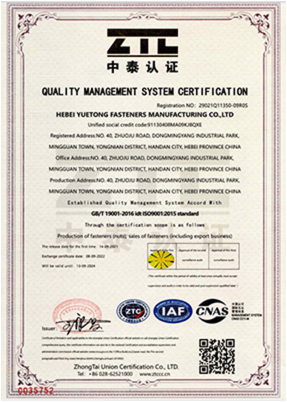

5. Industry Standards Different industries often have established standards and guidelines for bolt sizes and specifications. Familiarizing yourself with these standards can help ensure compliance and maintain safety in your projects. Organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide detailed specifications for various types of fasteners.

Conclusion

Selecting the right bolt size is essential for the success and safety of any construction or manufacturing project. By taking into account load requirements, material compatibility, environmental conditions, joint configurations, and industry standards, you can make a well-informed decision. Always remember that investing time in the selection process can yield significant long-term benefits, including improved structural integrity and reduced maintenance costs. In a world where safety and efficiency are paramount, the right bolt could make all the difference.