Jul . 31, 2024 09:17 Back to list

Exploring the Benefits and Applications of Countersunk Anchor Bolts in Construction Projects

Understanding Countersunk Anchor Bolts An Essential Component in Construction

Countersunk anchor bolts are a crucial element used in various construction applications, providing robust support and stability for structures. These specialized fasteners are designed to bear heavy loads while minimizing the risk of hazards such as corrosion, loosening, or failure. This article will delve into the characteristics, advantages, applications, and installation processes of countersunk anchor bolts, highlighting their significance in the construction industry.

Characteristics of Countersunk Anchor Bolts

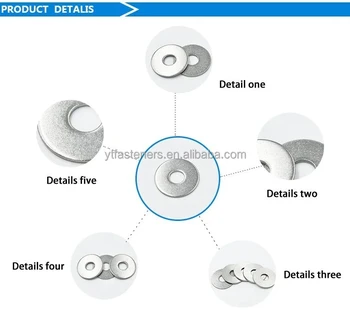

Countersunk anchor bolts are identifiable by their unique design, featuring a flat or tapered head that allows the bolt to sit flush with the surface of the material to which it is attached. This design minimizes protrusion, ensuring a smooth finish that is often necessary for safety and aesthetic purposes. These bolts are typically made from high-strength materials, such as stainless steel or carbon steel, which provide durability and resistance to various environmental factors.

The dimensions of countersunk anchor bolts can vary, with different diameters and lengths available to accommodate specific applications. The choice of size and material is crucial, as it must align with the load requirements and environmental conditions of the installation site. Additionally, countersunk bolts can come with different types of threads, including coarse and fine, depending on the requirements of the specific application.

Advantages of Countersunk Anchor Bolts

One of the most significant advantages of using countersunk anchor bolts is their unobtrusive design. Since the head of the bolt is recessed, it does not interfere with adjacent materials or equipment, which is especially important in areas with limited space or when a sleek appearance is desired. Furthermore, their flush finish helps reduce the risk of snagging or injury, making them ideal for pedestrian pathways or other high-traffic areas.

Moreover, countersunk anchor bolts provide excellent load distribution, which enhances stability and minimizes stress on the surrounding materials. This characteristic makes them suitable for securing heavy structures, such as machinery, bridges, and buildings. Additionally, the flat head allows for the use of washers, which can further improve load distribution and reduce the chance of bolt loosening over time.

countersunk anchor bolts

Applications of Countersunk Anchor Bolts

Countersunk anchor bolts are used across various industries and applications. In construction, they play a vital role in securing beams, columns, and structural elements to foundations and other supports. They are often found in bridge construction, where high strength and stability are essential. In the manufacturing sector, these bolts secure machinery and equipment, ensuring safe operation.

In addition to heavy construction, countersunk anchor bolts are also used in residential applications, such as attaching fixtures and supports to walls and floors. Their versatility makes them a favored choice in both commercial and residential projects.

Installation Process

The installation of countersunk anchor bolts typically involves several steps. Firstly, proper site preparation is essential. The surface where the bolt will be installed must be clean and free from debris to ensure a secure fit. Next, a hole is drilled into the base material, matching the diameter of the bolt. The countersink portion of the hole should be made to accommodate the head of the bolt.

Once the hole is prepared, the anchor bolt is inserted and fastened securely using the appropriate tools. It’s vital to follow manufacturer instructions for torque specifications to ensure the bolt is tightened adequately without risking damage to the material.

Conclusion

Countersunk anchor bolts are essential fasteners that play a critical role in various construction and manufacturing applications. Their unique design, coupled with their ability to provide robust support and stability, makes them indispensable in modern construction. By understanding their characteristics, advantages, applications, and proper installation methods, builders and engineers can ensure that they are utilizing these vital components effectively, ultimately contributing to the safety and longevity of structures.

-

Strong Clamps, Safe Lifting

NewsMay.07,2025

-

Reliable Rods for Strong Structures

NewsMay.07,2025

-

Hex Head Wood Screws in Daily Construction

NewsMay.07,2025

-

Hex Head Anchoring Solutions

NewsMay.07,2025

-

Effective Wire Rope Clamps for Secure Lifting

NewsMay.07,2025

-

Anchor Bolts for Secure Ceiling Installations

NewsMay.07,2025