Dec . 17, 2024 09:36 Back to list

ms flat washer

Understanding MS Flat Washers Importance, Applications, and Selection Guide

Flat washers are essential components in a variety of mechanical and structural applications. Among the different types of washers available, MS flat washers, made from mild steel (MS), play a significant role due to their strength, versatility, and cost-effectiveness. This article explores the characteristics, applications, and selection criteria of MS flat washers, providing a comprehensive guide for engineers, builders, and DIY enthusiasts.

What Are MS Flat Washers?

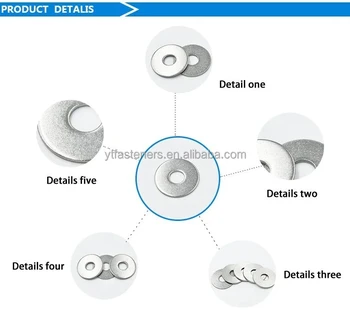

MS flat washers are circular plates with a hole in the middle, designed to distribute the load of a threaded fastener, such as screws and bolts. The primary function of a flat washer is to provide a larger surface area under the fastener head, thereby preventing damage to the work surface and optimizing load distribution. Typically made from mild steel, these washers can be treated with various coatings, such as zinc or black oxide, to enhance their corrosion resistance and overall durability.

Importance of MS Flat Washers

1. Load Distribution One of the main purposes of a flat washer is to spread the load of a bolt or screw evenly across a larger area. This prevents the fastener from embedding itself into the material and helps avoid indentation or cracking, particularly in softer materials like wood or plastic.

2. Protecting Surfaces In applications where the aesthetic and structural integrity of materials matters, MS flat washers prevent direct contact between fasteners and surfaces, thus reducing wear and tear. This protective layer is particularly crucial in automotive and machinery applications, where preventing damage can enhance longevity.

3. Vibration Resistance In dynamic environments where vibrations are prevalent, flat washers can help maintain the integrity of a connection. By providing a cushion between the fastener and the surface, they reduce the likelihood of loosening caused by movement.

4. Alignment Washers assist in aligning components during assembly, helping to ensure that the parts fit together correctly and operate as intended. This is especially important in precision engineering applications.

Applications of MS Flat Washers

ms flat washer

MS flat washers are utilized across various industries, demonstrating their versatility. Some common applications include

- Construction These washers are used in the assembly of structures and frameworks, providing stability and support to fasteners in place. - Automotive In vehicles, MS flat washers are found in a range of components, from engine assemblies to bodywork, ensuring that various parts stay securely fastened even under vibration and stress. - Manufacturing In machinery and equipment manufacturing, flat washers are vital for assembling parts that require both strength and flexibility. - Home Repair and DIY For home improvement projects, MS flat washers are commonly used in furniture assembly, plumbing, and electrical installations where fastening and stability are necessary.

Selecting the Right MS Flat Washer

When it comes to selecting the appropriate MS flat washer for your project, consider the following factors

1. Size The diameter of the washer should match the size of the fastener being used. Ensure that the inner diameter (the hole) accommodates the bolt or screw, while the outer diameter should provide adequate load distribution.

2. Thickness The thickness of the washer can impact load distribution and flexibility. In applications with higher loads, thicker washers may be necessary to prevent deformation.

3. Material Coating Depending on the environment in which the washer will be used, select a coating that enhances corrosion resistance. For outdoor applications, zinc-coated washers are often recommended.

4. Standards and Certifications Ensure that the flat washers meet industry standards and specifications (such as ASTM or DIN) relevant to your application, particularly in critical systems.

Conclusion

MS flat washers may seem like simple components, but their role in ensuring the safety, durability, and efficiency of various applications is substantial. By understanding their importance, range of applications, and selection criteria, professionals and DIY enthusiasts alike can make informed decisions, leading to better project outcomes. Whether in construction, automotive, manufacturing, or home improvement, these washers remain a fundamental element in any assembly, ensuring that things hold together securely for years to come.