Aug . 14, 2024 21:51 Back to list

Understanding the Importance of M8 Washer Outer Diameter in Fastener Applications for Enhanced Performance

Understanding the Importance of M8 Washer OD in Mechanical Applications

In the world of mechanical engineering and assembly, every component plays a critical role in ensuring the efficiency, stability, and durability of the overall structure. Among these components, washers, particularly M8 washers, hold significant importance. The term “M8” refers to a metric screw thread with a nominal diameter of 8 millimeters. The outer diameter (OD) of the washer is a vital specification that often dictates its suitability for particular applications. This article explores the significance of the M8 washer OD, its applications, and factors to consider when selecting the right washer.

What is an M8 Washer?

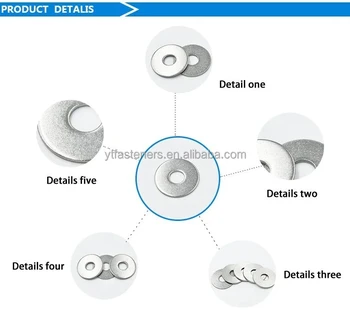

An M8 washer is a flat, circular piece of material, typically made from metals such as stainless steel, brass, or other alloys. It is used in conjunction with an M8 bolt or screw to provide a larger surface area for load distribution, prevent damage to the surface being fastened, and reduce the risk of bolt loosening due to vibration. The washer acts as a load-bearing surface that helps to spread the force applied by the bolt head across a wider area, preventing the material being fastened from deforming.

The Importance of Outer Diameter (OD)

The outer diameter (OD) of a washer is crucial for several reasons. First, it determines how well the washer can spread the load of the bolt or screw over the surface of the material being secured. A washer with an appropriate OD will ensure that the fastening joint remains strong and effective. An oversized OD may prevent the washer from fitting into tight spaces, while an undersized OD may not provide adequate support, leading to failure of the joint.

Moreover, the OD plays a role in reducing the risk of corrosion. By ensuring a good seal between the washer and the material, the OD helps to minimize the exposure of the joint to environmental factors such as moisture, which can lead to rust and degradation over time. In outdoor or high-humidity applications, selecting a washer with the correct OD, along with appropriate material choices, can significantly enhance the longevity of the component.

m8 washer od

Applications of M8 Washers

M8 washers are used in a diverse range of applications across various industries. In the automotive sector, they are commonly employed in engine assembly, suspension systems, and bodywork to ensure secure fastening. In construction, they help secure components in structural applications, supporting beams, and frames. Additionally, in the electronics industry, M8 washers are often utilized in equipment assemblies where precision and reliability are crucial.

Factors to Consider When Choosing M8 Washers

When selecting M8 washers, the outer diameter is not the only essential measurement. It is also vital to consider the inner diameter (ID), thickness, and material. The ID must match the M8 bolt or screw, ensuring a snug fit. The washer's thickness can affect its load-bearing capacity—thicker washers generally provide better support but may also add weight to the assembly.

Furthermore, the material of the washer should be chosen based on the environmental conditions it will face. For instance, stainless steel washers are excellent for applications exposed to moisture due to their corrosion resistance, while aluminum washers may be preferred for lightweight assemblies.

Conclusion

The M8 washer OD is a vital specification that must not be overlooked in mechanical assembly. Understanding its importance helps engineers and designers choose the right washer for their applications, ultimately leading to more robust, reliable, and durable structures. By paying attention to all relevant factors, including OD, material, and thickness, one can ensure the integrity of their fastening solutions across a wide array of industries. As technology continues to advance, the role of seemingly simple components like washers remains critical in the pursuit of engineering excellence.