dec. . 10, 2024 04:05 Back to list

Custom Flat Washers for Enhanced Performance and Versatile Applications in Various Industries

Custom Flat Washers An Essential Component in Modern Engineering

In the world of manufacturing and engineering, even the smallest components play a crucial role in ensuring the performance and reliability of an assembly. One such component is the flat washer, a seemingly simple disc-shaped piece often overlooked in design considerations. However, custom flat washers have become indispensable in various applications, providing essential functions that enhance mechanical integrity and performance.

What is a Flat Washer?

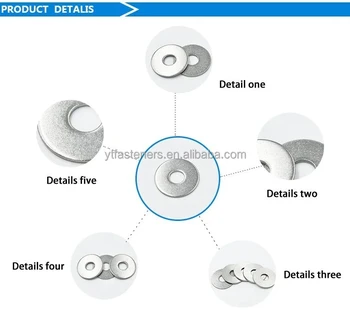

A flat washer is a thin, disc-shaped component with a hole in the middle, designed to distribute load and provide a smooth surface for fastening systems. Flat washers are primarily used to prevent damage to the surface of the material being fastened, provide insulation between components, and increase the load-bearing area of a bolt or screw. They can also be used to fill gaps between components, offering additional benefits in vibration resistance and stability.

The Importance of Customization

While standard flat washers serve many applications, there are instances where custom flat washers are necessary. Different projects may require specific materials, sizes, thicknesses, or coatings, and standard washers may not meet these precise demands. Custom flat washers are tailor-made to fit unique application requirements, ensuring optimal performance and durability.

Material Selection

One of the primary factors in customizing flat washers is selecting the right material. Common materials for washers include steel, stainless steel, brass, nylon, and rubber. The choice depends on various factors such as corrosion resistance, temperature tolerance, and load-bearing capacity. For instance, in industries like aerospace or automotive, where components are subjected to extreme conditions, custom washers made from high-strength alloys or corrosion-resistant materials can significantly enhance performance and longevity.

Size and Thickness

Another critical aspect is the size and thickness of the washer. Custom flat washers can be manufactured to precise dimensions tailored to the application. In high-stress environments where traditional washers might not perform adequately, customizing thickness can provide additional reinforcement, ensuring that the assembly remains secure under load.

custom flat washers

Applications of Custom Flat Washers

Custom flat washers are used across various industries, reflecting their versatility and importance.

- Construction and Structural Applications In structural engineering, custom washers help distribute loads in areas where bolts and screws are used to connect steel beams, wooden frames, or concrete structures. Their ability to spread the load reduces the likelihood of material fatigue and failure.

- Automotive Manufacturing In the automotive industry, where safety and performance are paramount, custom flat washers are employed in critical applications such as engine assembly, suspension systems, and braking mechanisms. Their precision manufacturing and material selection ensure that vehicles can withstand rigorous testing and provide reliability on the road.

- Aerospace Industry The aerospace sector demands the highest standards of quality and performance. Custom flat washers used in aircraft must be able to handle high speeds, extreme temperatures, and significant pressure changes. These washers play a vital role in ensuring safety and efficiency in flight.

- Electronics and Electrical Applications Custom flat washers are also essential in electronic devices and electrical connectors. They can provide insulation and help secure connections, preventing short circuits and ensuring the integrity of the electrical system.

Benefits of Using Custom Flat Washers

The use of custom flat washers presents several advantages. They provide better fit and performance tailored to specific applications, reduce maintenance needs, and can enhance the overall efficiency of an assembly. Moreover, by using custom washers, manufacturers can ensure that their products meet industry standards and regulations, promoting safety and reliability.

Conclusion

In conclusion, while flat washers may appear to be simple components, their importance cannot be understated. The advent of custom flat washers has revolutionized how engineers and manufacturers approach assembly design and quality assurance. By meeting specific application requirements through customization, these washers contribute significantly to the structural integrity and reliability of various products across industries. As technology advances and the demand for precision increases, the role of custom flat washers will only expand, further solidifying their position as essential components in modern engineering.

-

The Ubiquitous Reach of DIN934 in Application Realms

NewsMay.16,2025

-

Exploring Different Bolt Types

NewsMay.16,2025

-

Cracking the Code of Sleeve Anchor Mastery

NewsMay.16,2025

-

Clamp Design Principles,Types and Innovations

NewsMay.16,2025

-

Artistry Inspired by the Humble Anchor Bolt

NewsMay.16,2025

-

A Deep Dive into Screw Types

NewsMay.16,2025