Dec . 05, 2024 16:57 Back to list

Universal Precision Fasteners for Reliable Applications and Enhanced Performance in Various Industries

The Importance of Universal Precision Screws in Modern Engineering

In today's rapidly advancing technological landscape, the significance of precision components cannot be overstated. Among these components, universal precision screws play a crucial role across various industries, from aerospace to consumer electronics. Understanding the nuances of these screws, their applications, and advantages not only helps engineers and manufacturers but also enlightens consumers about the intricate details that go into the products they use daily.

What Are Universal Precision Screws?

Universal precision screws are specially designed fasteners that ensure a seamless fit in a wide range of applications. Unlike standard screws that may vary in dimensions or thread types, universal precision screws maintain stringent manufacturing tolerances, allowing for high compatibility and interchangeability with various components. Typically made from high-quality materials such as stainless steel, titanium, or carbon steel, these screws offer durability and resistance to corrosion, making them suitable for diverse environments.

Applications Across Industries

The versatility of universal precision screws is a significant factor in their widespread usage. In the aerospace sector, where safety and reliability are paramount, these screws are used in critical applications such as fuselage assembly and engine mounting. The precision of these screws ensures that structural integrity is maintained under high-pressure conditions, contributing to the overall safety of air travel.

In the automotive industry, universal precision screws play a vital role in assembling various components, ranging from engine parts to interior fittings

. As vehicles become increasingly sophisticated with advanced technologies, the need for reliable fastening solutions remains essential. Precision screws facilitate easier assembly and repair processes, ultimately enhancing productivity and lowering manufacturing costs.universal precision screws

Consumer electronics also benefit immensely from the use of universal precision screws. Devices such as smartphones, laptops, and tablets require tiny yet powerful screws to maintain their compact design while ensuring robust construction. The standardization of screw types in these devices allows manufacturers to streamline production, reduce costs, and simplify repair processes, benefiting the end-users.

Advantages of Universal Precision Screws

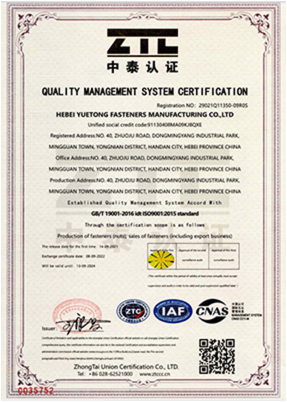

One of the primary advantages of universal precision screws is their consistency in quality. Due to stringent quality control processes, these screws are manufactured to meet specific standards that guarantee reliability and performance. This consistency reduces the risks of mechanical failures, which can be costly and dangerous in critical applications.

Moreover, universal precision screws are designed for ease of use. Their standardized dimensions simplify the assembly process, allowing manufacturers to optimize production lines and minimize the time required for assembly. For consumers, the standardization means that repairing or replacing parts in electronic devices or machinery is often more straightforward, as compatible universal precision screws are readily available.

The Future of Fastening Technology

As industries continue to evolve, the demand for innovative fastening solutions will only increase. Universal precision screws are likely to evolve with these demands, embracing advancements in materials and manufacturing processes. Emerging technologies, such as 3D printing and smart materials, may revolutionize how screws are designed and produced, potentially leading to even greater versatility and efficiency.

In conclusion, universal precision screws play a pivotal role in modern engineering, offering reliable, high-quality fastening solutions across various industries. Their versatility, consistency, and ease of use make them a key component in the manufacturing and assembly processes of countless products we rely on daily. As we look to the future, the evolution of fastening technology will undoubtedly continue to enhance the performance and safety of diverse applications, showcasing the indispensable nature of universal precision screws in our everyday lives.