Eyl . 25, 2024 11:45 Back to list

Understanding M6 Threaded Studs and Their Applications in Various Industries

Understanding M6 Threaded Studs Specifications and Applications

The M6 threaded stud is a pivotal component in the realm of manufacturing, engineering, and construction. Characterized by its metric dimensions, the “M” signifies that it follows the metric system, and “6” refers to its nominal diameter of 6 millimeters. This article delves into the specifications, advantages, and applications of M6 threaded studs.

Specifications

An M6 threaded stud typically features a length that can range from a few millimeters to several centimeters, depending on the requirements of the application. The threads are designed according to the ISO 965 standard, ensuring compatibility with other metric threaded components. The standard pitch for M6 threads is 1.0 mm, which is the distance between adjacent threads.

Materials used for M6 threaded studs can vary widely. Common choices include stainless steel, carbon steel, and alloy steel, each offering distinct advantages in terms of strength, corrosion resistance, and weight. Stainless steel studs are particularly favored in applications where corrosion resistance is paramount, such as in marine and chemical environments. Meanwhile, carbon steel options provide excellent tensile strength, making them suitable for heavy-duty applications.

Advantages

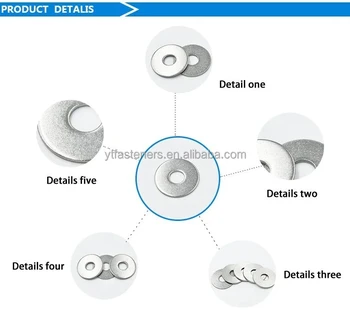

One of the primary advantages of using M6 threaded studs is their versatility. They can be utilized in numerous configurations, such as bolted connections, anchor points, or fastening systems. Their metric nature means that they seamlessly integrate with a range of metric nuts and washers, facilitating ease of assembly and disassembly.

m6 threaded stud

Additionally, threaded studs provide a reliable method of creating strong mechanical connections. The full-length threads allow for maximum engagement with nuts and other fasteners, ensuring that joints can withstand significant shear and tensile forces. The consistency of the metric specification also simplifies design processes, enabling engineers to make precise calculations for load-bearing applications.

Applications

M6 threaded studs find applications across various industries. In the automotive sector, they are commonly used to secure engine components, exhaust systems, and wheels. In construction, these studs serve as anchor points for structural framing and can be utilized in concrete applications when combined with nuts and inserts.

The electronics industry also employs M6 threaded studs for mounting circuit boards and securing housings. Their compact size and strong fastening capabilities make them ideal for applications where space is limited but strength is still required.

Furthermore, the DIY community appreciates M6 threaded studs for home projects, furniture assembly, and repairs. Their availability in various hardware stores and online marketplaces makes them easily accessible for enthusiasts and professionals alike.

Conclusion

The M6 threaded stud is a fundamental component that exemplifies strength, versatility, and reliability. Whether in high-tech industries or everyday applications, these studs provide essential support and stability. Understanding their specifications and applications can help in selecting the right threaded stud for any project, ensuring safe and effective assembly. As engineering and manufacturing continue to evolve, the role of the M6 threaded stud remains vital in creating robust and durable connections.

-

The Ubiquitous Reach of DIN934 in Application Realms

NewsMay.16,2025

-

Exploring Different Bolt Types

NewsMay.16,2025

-

Cracking the Code of Sleeve Anchor Mastery

NewsMay.16,2025

-

Clamp Design Principles,Types and Innovations

NewsMay.16,2025

-

Artistry Inspired by the Humble Anchor Bolt

NewsMay.16,2025

-

A Deep Dive into Screw Types

NewsMay.16,2025